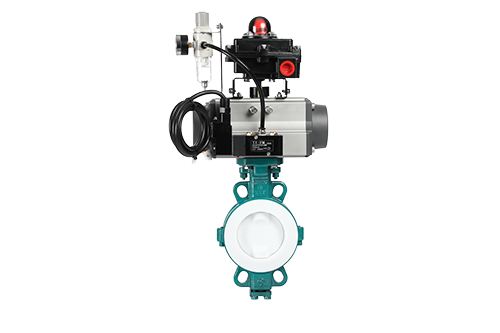

Fluorine lined butterfly valve pneumatic fluorine lined butterfly valve overview

Pneumatic fluorine lined butterfly valve overview

D671F type sealing lining tetrafluoron, D671F4 type full lining tetrafluoron, D671F46 full lining polyperfluorinated ethylene propylene three kinds. The pneumatic butterfly valve is composed of fluorine lined butterfly valve, pneumatic actuator, positioner, limit switch, solenoid valve, filter pressure reducing valve and other components combined into a complete set of automatic control valves. D671F pneumatic fluorine lined butterfly valve shell and valve plate optional: gray cast iron, nodular cast iron, carbon steel, stainless steel four materials; Lining material optional: F4, F46, PFA and other fluorine containing materials.

Pneumatic fluorine lined butterfly valve function

Suitable for temperature ≤150℃ various strong corrosion, weak corrosion or cleanliness requirements of the working conditions, in food, medicine, chemical, petroleum, electric power, textile, paper and other water supply and drainage, gas pipeline for regulating flow and blocking medium. Pneumatic fluorine lined butterfly valve with a spherical sealing surface lined with ptfe coated butterfly plate, the valve operation is light, tight sealing performance, long service life; It can be used to cut off or adjust the flow quickly. Suitable for applications requiring reliable sealing and good regulating characteristics. The valve body adopts split type, the seal at both ends of the valve shaft is controlled by the rotating base surface fluorinated rubber between the butterfly plate and the valve seat; Ensure that the valve shaft does not contact the fluid medium in the chamber. It is widely used for conveying liquids and gases (including steam) in various types of industrial pipelines, and for the use of severely corrosive media, such as sulfuric acid, hydrofluoric acid, phosphoric acid, chlorine, strong alkali and other highly corrosive media.

Pneumatic fluorine lined butterfly valve structure characteristics

1, novel design, reasonable, unique structure, light weight, fast opening and closing.

2, operating torque is small, easy to operate, labor-saving dexterity.

3, can be installed in any position, convenient maintenance.

4, sealing parts can be replaced, reliable sealing performance to achieve two-way sealing zero leakage.

5, sealing material aging resistance, corrosion resistance, long service life and other characteristics.

Pneumatic fluorine lined butterfly valve standard

Design standard: GB/T2238-1989

Flange connection size :GB/T9113.1-2000; GB/T9115.1-2000; JB78

Length :GB/T12221-1989

Pressure test :GB/T13927-1992; JB/T9092-1999

ZHEJIANG VALVE FLUORINE TECHNOLOGY CO., LTD

-

service hotline18106790007

-

service hotline13777787208

-

RichScan

RichScan

Address: No. 84, Hetou Long West Road, Suchuan Village, Yaoxi Street, Longwan District, Wenzhou